Toutes nos prestations

QUALITY CONTROL MANAGEMENT "Q.C.M."

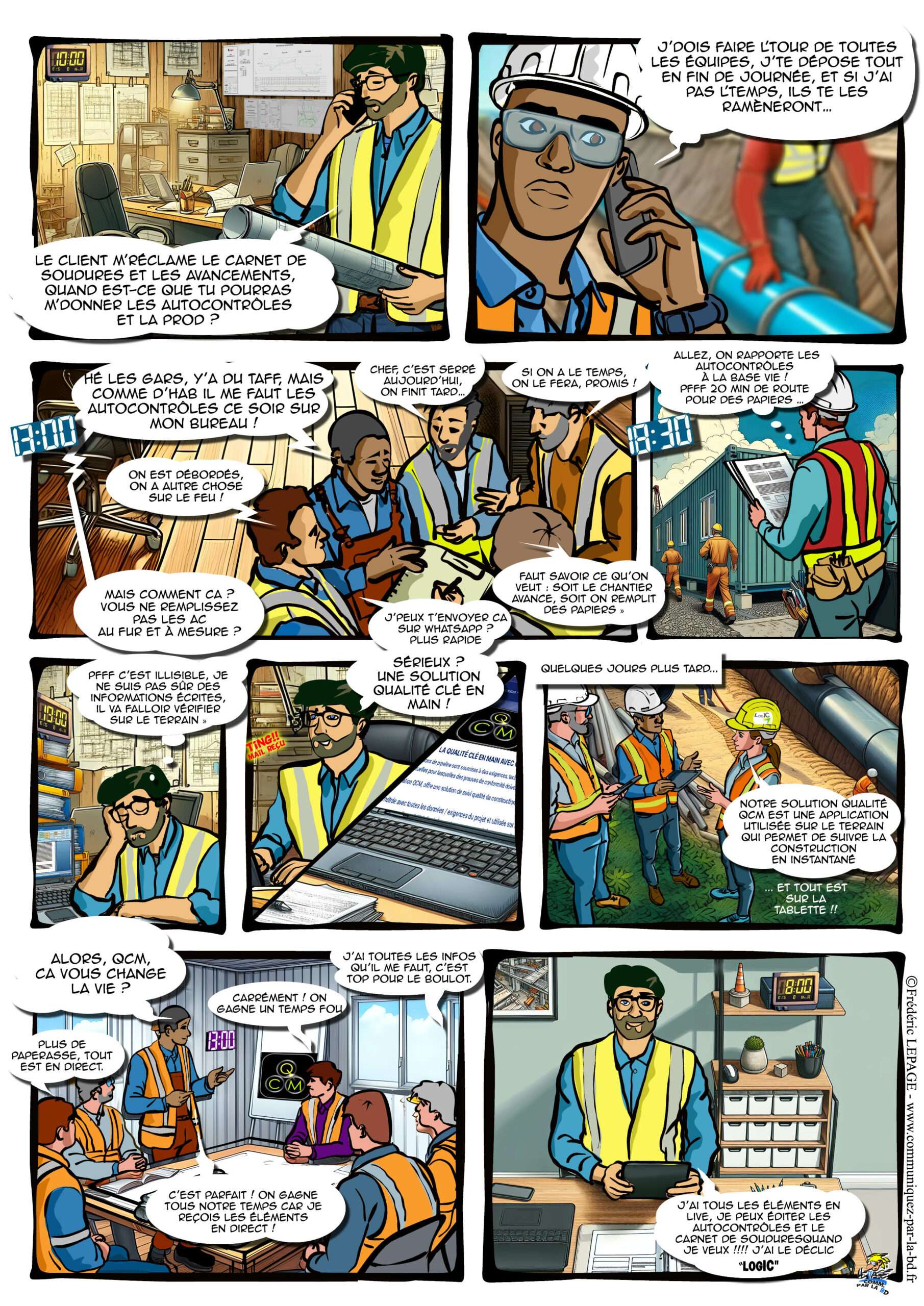

Pipeline constructions are subject to technical, regulatory, and contractual requirements for which proof of compliance must be recorded.

Mastering the traceability, quality and compliance of the pipelines built is essential for their commissioning. It requires the definition of quality assurance plans that involve the implementation of control and verification operations.

The QCM application provides a reliable and instantaneous quality control solution for construction.

Configured with all project data/requirements and used on-site, it provides real-time information availability from anywhere!

Project configuration

This step is done before construction work begins and involves setting up all the necessary input data. This input data is used to provide field teams with instant access to all the information needed for their respective activities.

During this phase, the formalism of the documents resulting from the application is also defined according to the requirements of the end user. This includes the type of PV, reports, solder book format, necessary statistics, and more.

In order to ensure the traceability of the construction, the material, organisational and human resources available and qualified are allocated to the project (identification and qualification of welders, welding procedure, compliant measuring equipment, list of tubes, etc.).

The technical requirements and tolerances are set specifically for each site so that the conformity of the construction can be checked automatically (bending, welding, cutting).

The configuration of the application is crucial to ensure the proper functioning of our digital solution, and it serves as a starting point for real-time monitoring of construction and compliance with the site’s quality assurance plan.

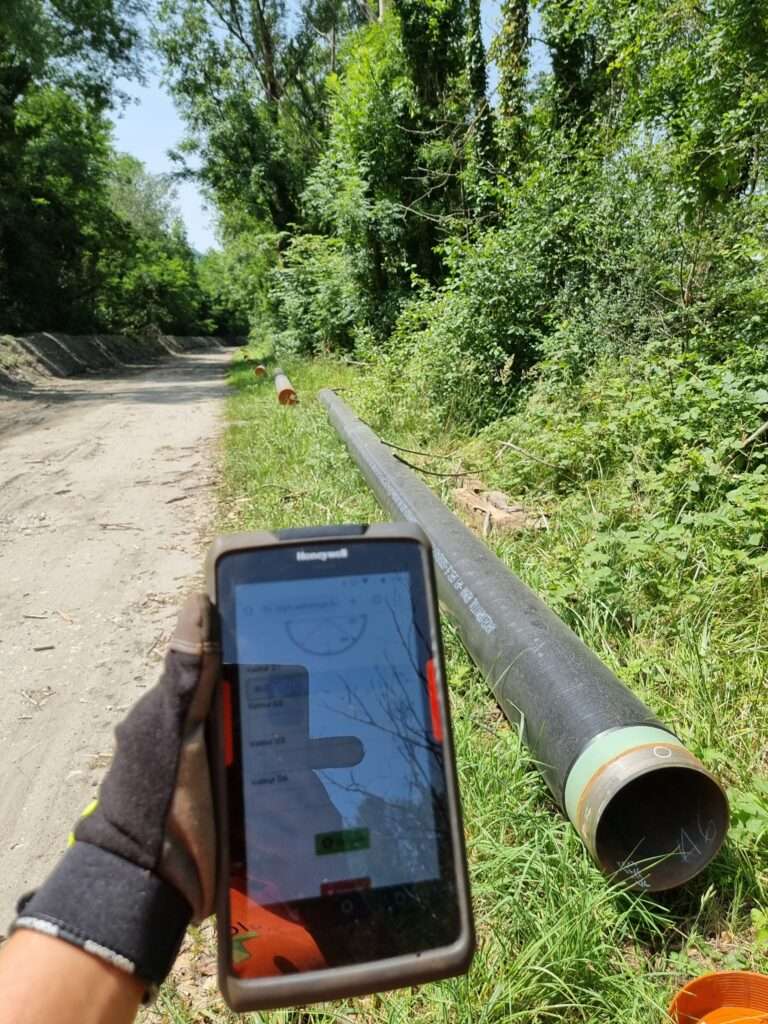

Use in the field

The app is used by team leaders during the following construction phases:

- Pipe control

- Pipe storage

- Pipe bending

- Pipe cutting

- Pipe sledding

- Pipe welding

- Weld coating

- Lowering

The use during the construction phases directly in the field, allows to have the necessary information and to geolocate all the operations. In this way, the data is controlled instantly and available on the construction site as well as remotely

Quality Management

Since all data entered in the field is analyzed in real time by QCM, any detected deviations are instantly notified to the operator as well as to the back office and can be processed immediately.

The results of non-destructive testing of welds are recorded on receipt of the test reports supplied by the testing body.

Quality documents

The self-checks are work done proof, they allow to decide on conformity and to know work progress.

These self-checks are carried out on site and must be transmitted to project manager within a very short time (generally within 24 hours after completion of the work).

Thanks to construction monitoring digitalization , the self-checks are generated automatically!

The use by construction teams in the field allows for entering production elements and benefiting from instant control.

The entered data feeds into the self-checks, which can be transmitted directly to the project manager.

This document is regulatory and lists all the construction data of the pipeline. It is essential for the commissioning of the facilities.

Mastering the traceability of pipes and welds is necessary for feeding the welding book.

The use of QCM throughout the construction process enables instant and automatic feeding of the welding book.

The welding book becomes available in real-time, without a dedicated phase for data recording.

Statistics and reports

The construction monitoring is done in real time, QCM offers the possibility to generate progress reports.

Welding statistics are automatically calculated based on welding and non-destructive testing data. This ensures compliance monitoring of welds (by welder, by welding procedure specification, and by period).

benefits

Construction data available in real time, anywhere

Construction data available in real time, anywhere

Reducing the environmental footprint

Reducing the environmental footprint

Reduced costs (management, travel)

Reduced costs (management, travel)

![]() Geolocation-based construction

Geolocation-based construction

![]() Risk reduction (SST)

Risk reduction (SST)

Control of compliance and traceability

Control of compliance and traceability

Secure data storage

Secure data storage